26th March 2015 London: The Plantworx Innovation Awards were announced yesterday at a ceremony in Central London at the Gherkin. The Plantworx team were joined by the representatives of the winning companies, sponsors and the Judges.

The legislation-driven need to reduce emissions and fuel consumption to comply with EU Stage IV regulations tested the innovation muscles of the construction equipment industry. And some of the results – the development of hybrid-powered excavators, for example – have advanced the industry’s environmental cause rather more quickly than anyone had previously imagined possible.

Innovation Unleashed

And yet, with OEM research and development budgets targeted almost exclusively towards the sole aim of making equipment cleaner and greener, wider “above-the-bonnet” innovation has been stymied for a number of years. As a result, non-engine-related developments in the field of construction plant and equipment have generally been in the form of small, incremental changes and improvements: a new in-cab display here; a new shape of engine hood there.

But with Stage IV regulations largely satisfied and the push towards Stage V still several years away, equipment manufacturers have emerged from a period of enforced focus. And the result has been a surge in true innovation; a fact highlighted by the sheer diversity of the entrants in the PlantworX 2015 awards. And while some of the entries remain engine-related, the way in which those engines operate or are being harnessed is totally new and unprecedented.

Judging Panel

Against a background of such unbridled innovation, it was important that the judging panel was representative of the entire construction and construction equipment industry and as diverse as the award entries themselves. Each member of the panel was, therefore, hand-picked to look at the entrants from a different perspective.

Those judges were:

- Wendy Bates, innovation and customer experience director of Speedy Services – a lady in tune with the ever-changing needs of construction equipment users

- Neil Edwards, chief executive of The Builders’ Conference trade association which is dedicated to enhancing industry efficiency

- Rich Holt of Fabrications by Design; a metal bending master who spends much of his time modifying OEM equipment to better suit customer needs

- Kevin Minton, director of the Construction Plant-hire Association (CPA) whose members buy the vast majority of the equipment sold in this country

- Austin Wilkinson of AW Demolition, an owner/operator who splits his time between office and machine and who sees equipment from an operator’s perspective.

Between them, the judges had to choose the very best of the best in five key categories: Green; Safety; Security; Engineering; and Efficiency. Each category had multiple entrants and each was hotly contested by major multi-national OEMs offering a full range of equipment, and by smaller specialist companies with a very specific expertise in a particular field.

The judging was far from easy with each judge bringing their own perspective and preference to bear. But ultimately, the winners in each category shone through.

Safety

Sponsored by

CPA (Construction Plant-hire Association)

A key focus of construction equipment design and development is to ensure the safety of the person operating the machine, their fellow workers, pedestrians, and local residents.

The entrants in this category ranged from a safer way to cut metal in the workshop or in the field from Hypertherm, through a remote-controlled demolition machine from Brokk, to a new kind of Personal Protective Equipment (PPE) from GSS Elite.

This turned out to be one of the most hotly-contested categories with the judges split and each endorsing a product or solution that might benefit their own specific corner of the industry.

Ultimately, after much negotiation and not a little compromise, the judges whittled it down to just two favourite entrants.

The “glow-in-the-dark” personal protective equipment from GSS Elite was highly commended and earned the backing of several judges.

But ultimately, the IPAF smart card system, which ensures that only qualified operators can operate a specific access platform, was named the category winner.

- Highly Commended – Elite GSS

- Winner – IPAF

Green

Sponsored by

Perkins

The drive to meet Stage IV engine emissions regulations, not surprisingly, continued to hang over the Green Award category. But it was not the engines themselves that earned the plaudits. Rather, it was the way in which clean power was harnessed that truly caught the judges’ eyes.

Both JCB and Firefly utilised state-of-the-art technology to bring hybrid power to the field of electrical power generation; Wacker Neuson brought electric power to play in the highly-competitive compaction sector; and Morris Site Machinery utilised an advanced control system to run three lighting towers from a single power source with no loss in performance.

But in the Wacker Neuson 803 mini excavator, the judges identified one of the most innovative entrants in this year’s awards. Utilising diesel to travel to and from its work position before switching to electric drive to allow it to work in confined spaces or applications where emissions cannot be tolerated, the Wacker Neuson was a clear winner. “Wacker Neuson have taken a radical and innovative approach to allow this machine to work inside,” the judges said. “This machine is a significant breakthrough in equipment design.”

- Highly Commended – JCB IntelliHybrid generator

- Winner – Wacker Neuson 803 mini excavator

Security

Sponsored by

CEA (Construction Equipment Association)

With plant and equipment theft and online fraud showing no signs of abating, the protection of industry assets remains a key focus.

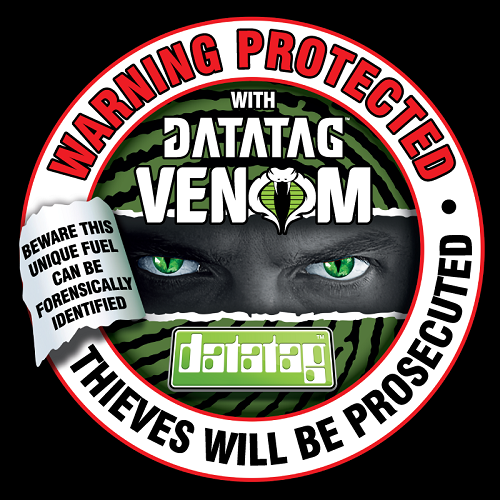

From the outset, the security category was a two-horse race. In red was the International Powered Access Federation with its machine-readable card which can be used to ensure that only trained operators can use aerial work platforms (AWPs) on site. And in blue corner was industry security stalwart Datatag with its “DNA for fuel” system to prevent fuel theft and to aid in its recovery in the event of a theft.

The IPAF Smart PAL Card looks the same as the standard PAL Card but is marked by a wireless icon and has a chip embedded in it. The data in the chip can be read by a card reader fitted to the machine. The reader can be set up to accept certain data which in turn will allow the machine to be operated. This data includes whether or not the cardholder (operator) is trained, to what level and in which machine categories.

The judges all agreed that this was a “major leap forward for the security and safety of powered access equipment” and demonstrated “a willingness to embrace technology” for the good of the industry.

But with diesel fuel now viewed by criminals and organised crime gangs as a key target, the judges agreed that Datatag’s Venom system offered a broader industry-wide benefit. Indeed, it was the only entrant to achieve a unanimous nod among the judging panel. “Fuel theft costs the industry millions of pounds. With the use of this simple fuel additive, the police can trace fuel back to its rightful owner, aiding prosecutions and acting as a superb deterrent. Datatag Venom has the potential to make a major contribution to the fight against theft in the construction industry.”

- Highly Commended – International Powered Access Federation (IPAF)

- Winner – Datatag Venom

Engineering

Sponsored by

Leica

The broadest category in this year’s awards was also the most eagerly contested, attracting a record number of entries from the four corners of the plant and equipment sector. Entries ranged from a new dozer from Case and a new quick coupler from Worsley Plant through to an 11 tonne, 360 degree rotating tracked dumper from Cautrac to an electric drive wheel loader from Wacker Neuson that has been designed for work in inner city and zero emissions applications.

But there were two products in this category that shone through, primarily for their ability to do an existing task but to do it better.

One was a quick coupler that allows a machine operator to switch attachments safely and securely without leaving the cab of his machine; the other was a generator that harnessed hybrid engine technology to reduce fuel costs and to reduce the environmental impact of on-site electrical power generation.

The winners in the Engineering category are:

- Highly Commended – Worsley Plant Lehnhoff quick coupler

- Winner – JCB Inteli-Hybrid Generator

Efficiency

Sponsored by

CESAR

Ultimately, all construction plant and equipment is designed to enhance the efficiency of a process and to make the owner, operator or user more profitable as a result.

This category attracted more than 20 superb entries that ranged from state-of-the-art plant hire software for equipment tracking from InspHire; a Morooka 11 tonne tracked dumper with the ability to dump its load through a full 360 degrees; a low-cost but highly efficient plasma cutting system from Hypertherm; and an equipment refuelling bowser capable of storing both diesel and AdBlue in a single, easy-to-transport unit.

The judges agreed that the AdBlue fuel bowser from Western Global helped overcome a specific refuelling challenge. But they ultimately agreed that a new Intelligent Machine Control excavator designed to make machine operation easier and more accurate should win the Efficiency category crown.

The winners in the Efficiency category are:

- Highly Commended – Western Global AdBlue fuel bowser

- Winner – Komatsu PC210i-10 excavator

Elite Awards

Sponsored by

PlantworX

With the winners of each category agreed, the judging panel was then required to choose the very best of the very best who would then be awarded an Elite Award.

In true Olympian style, the Elite Awards were divided into Bronze, Silver and Gold categories, with the Gold Award winner being crowned this year’s key innovator.

Once again, the discussion was heated and prolonged; the case for each winner equally valid; and several entrants – notably the JCB Inteli-Hybrid generator and the Komatsu PC210i-10 excavator – came within a whisker of landing an Elite award.

But, in the end, the judges reached parity around three highly-innovative and deserving Elite award winners. And it is notable that all three are totally new products, not mere incremental improvements on a proven theme; that all three embrace the use of modern technology to satisfy a specific customer demand; and that all three did not even exist when the first PlantworX exhibition took place in 2013.

And the winners are:

- Bronze – Wacker Neuson 803

- Silver – IPAF smart card system

- Gold – Datatag Venom

Visitor registration is now open for PLANTWORX and entry is free for more details and to see a full exhibitor list visit www.plantworx.co.uk. Put 2nd, 3rd and 4th June in your diary and we’ll see you at Bruntingthorpe Aerodrome, Leicestershire